Inventory is at the center of an ecommerce business. Ecommerce inventory management offers business owners benefits on multiple fronts, from streamlined warehousing operations to improved profitability.

Even without considering those benefits, ecommerce inventory management is almost a necessity for online businesses — and more so as they grow.

Think about it.

How would you feel when you order a bag of dog food every month, but this month the ecommerce store says it’s sold out? You’d probably look for dog food elsewhere. If the new store managed to offer a better customer experience, you’d likely stick with them.

But ecommerce inventory management ensures that you always have at least a few units of inventory in your warehouse to avoid losing business and loyal customers because of stockouts.

Don’t know how to manage ecommerce inventory? We’ll help you get familiarized with some of the best ecommerce inventory management techniques out there in this guide.

Here’s what you’ll learn:

- Ecommerce Inventory Management

- 5 Benefits of Ecommerce Inventory Management

- Final Thoughts: Ecommerce Inventory Management

Ecommerce Inventory Management

You need to look at multiple factors for ecommerce inventory management. For instance, check how quickly inventory was sold in the past, how fast you expect to sell it in the future, when you should order more inventory, how much you should order, and so on.

There are various ecommerce inventory management techniques that help address these issues. We’ll discuss them below.

1. Set PAR Level

You’ve probably unknowingly thought about periodic automatic replacement (PAR) level when considering the question of how to manage ecommerce inventory.

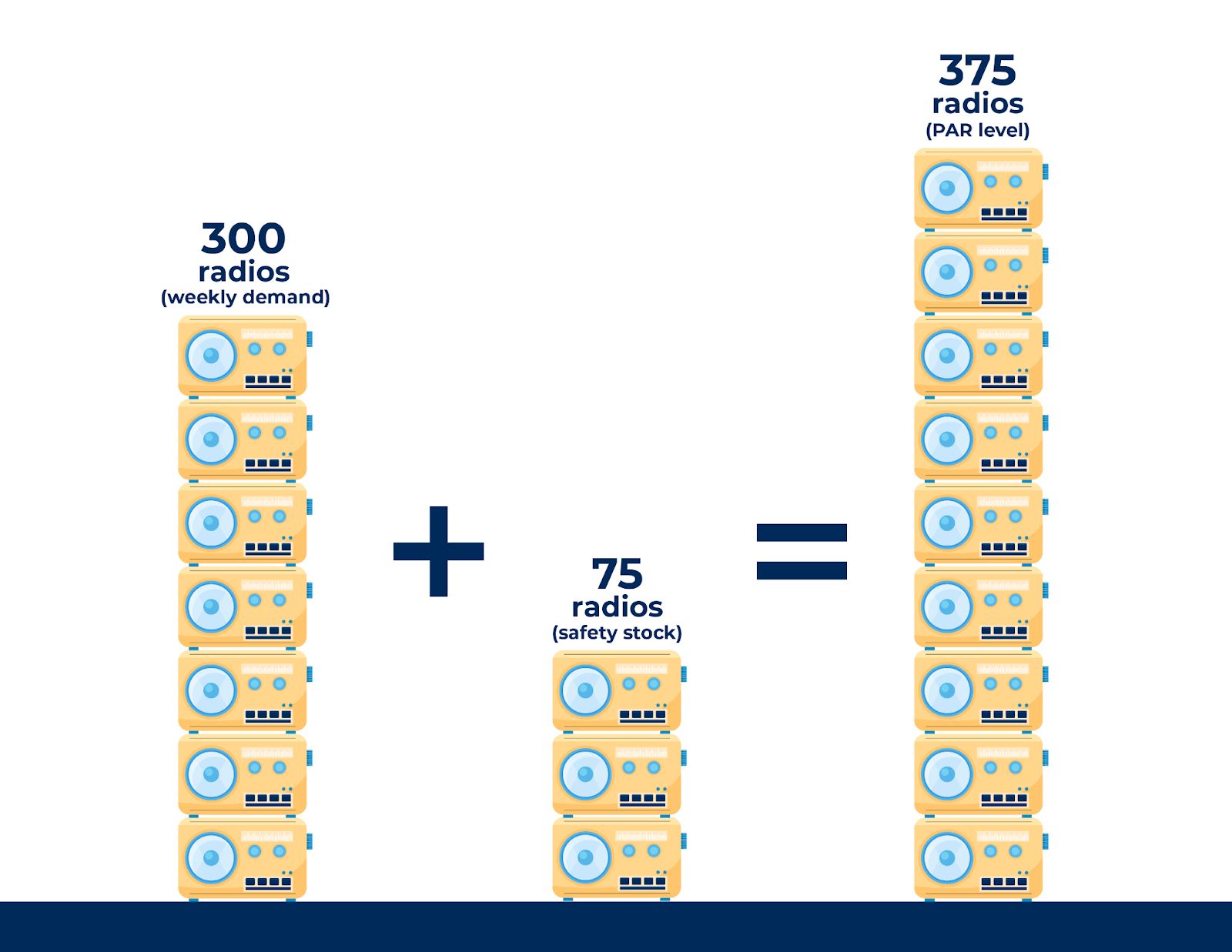

PAR level is the number of units in inventory required to meet the demand for the time your supplier usually takes to deliver the next order (also called lead time). It also accounts for some extra units as a cushion for a sudden surge in demand or unexpected delays in delivery.

PAR is also often referred to as safety stock.

For example, say you sell vintage radio sets. You sell close to 300 radio sets every week, which is also how long it takes for the next batch to reach you after you place an order with the supplier.

In that case, you can use 375 radios as your PAR level. The 300 radios meet your weekly demand, and 75 extra radios (an estimated number) can cover you in case people want to buy more from you during the week.

By the time you sell these radios, you’ll receive your new batch from the supplier and bring your stock levels back up.

On WooCommerce, you can set a Low stock threshold. The built-in option acts as a trigger and notifies you when your stock goes below a certain level.

This ecommerce inventory management technique ensures that you always have enough inventory to meet your customers’ demands without holding too much inventory at a time.

2. Forecast Inventory Needs

If you prepare monthly, quarterly, and yearly budgets, you know how difficult it can be to forecast your inventory needs. You can make an educated guess and look at historical sales data, but your estimates will always be at least slightly off from the actual sales.

The reason? Volatility in demand. Multiple external factors outside your control — such as the economy, wars, seasonality, and pandemics — influence customer demand for your inventory.

Note that the inventory forecasting technique doesn’t apply if you sell perishable goods. For instance, if you sell vegan milk in your ecommerce store, you won��’t need to forecast the demand for the next quarter.

Planning your inventory needs right at the beginning of a period gives you a framework for placing purchase orders and expected sales patterns. When you know when you’ll need how much inventory and have planned for it, you’re much less likely to experience stockouts.

3. Use EOQ

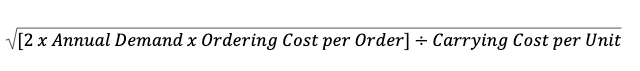

Economic order quantity (EOQ) is the optimum quantity you should order based on the demand, per-order cost, and cost of obsolescence.

While this ecommerce inventory management technique may seem insignificant, the effect it can have in the long-term is remarkable — especially if your turnover is high.

Here’s the formula for EOQ:

The annual demand is the number of units you expect to sell during the current year. The ordering cost (or the order fulfillment cost) is the cost of placing an order with your supplier. It includes the cost of freight but not the cost of goods itself.

The carrying cost is a little trickier. It includes both explicit and implicit costs.

First, you should calculate the cost of storing a unit of inventory in the warehouse.

Account for things like warehouse insurance, depreciation of racks on which the inventory is stored, cost of obsolescence (i.e., cost of units that generally end up in an unsellable condition when stored for very long), and other costs specifically associated with inventory storage.

Second, you should also account for the opportunity cost of inventory value. For instance, if you overstock $10,000 worth of inventory, you could be earning a 3% interest on that money. Since you’ve invested it in inventory instead, you’re now earning $300 less.

Based on these costs, the EOQ formula will give you an optimal order quantity which will minimize both your total annual ordering costs and total annual carrying costs.

Each time you reach the reorder point (i.e., your PAR level), you can place an order based on the EOQ to ensure financial efficiency.

4. Prioritize Inventory Items With ABC

The ABC approach to ecommerce inventory management involves grouping inventory items based on their value, where items in group A are the most valuable. ABC analysis draws from the Pareto principle, according to which 20% of inventory accounts for 80% of your revenue.

The value of stock-keeping units (SKUs) may often be significantly different, so there’s no exact grouping methodology you need to follow. But you can use the following as a framework:

- A = 10% of your inventory that are high-value items bringing 70% of your revenue.

- B = 20% of your inventory that are mid-value items bringing 20% of your revenue.

- C = 70% of your inventory that are low-value items bringing 10% of your revenue.

You can determine the value of SKUs as:

Annual Number of Units Sold x Cost per Item

Essentially, it’s the amount of revenue that each SKU contributes to your total revenue. Once you’ve classified the SKUs, you can focus your optimization efforts on class A items.

Class A items are usually fast-moving products that bring a large chunk of value to your business. You can allocate more warehouse space to them and minimize storage expenses on less popular inventory items.

5. Use JIT Inventory

Just-in-time inventory (JIT, also known as the Toyota Production System) is an inventory management system where goods are received from suppliers only as they’re needed. The fundamental idea behind JIT is to take on more risk in exchange for a reduced cost of storage and obsolescence.

With JIT, you keep enough inventory to meet customer demand, but no more. For instance, if you estimate that you’ll need 200 units of product A during the month of June 2022, you only order 200 units. Should you need more, you place another order.

The key here is finding a reliable supplier who can deliver orders quickly. At the end of June, you’ll estimate the inventory required for July and so on. If your supplier frequently delays deliveries, it can have a huge negative impact on your business.

Implementing JIT for ecommerce can be challenging because there’s little room for error. If you’re a high-growth ecommerce business, your inventory control needs to be dynamic.

Given the risks of stockouts owing to supply chain failure, implementing JIT inventory can be a tough nut to crack in an ecommerce setting. But if done right, it can produce significant cost savings.

6. Use Inventory Management Software

Inventory management software offers a suite of inventory control functionality that can provide valuable insights and streamline ecommerce inventory management.

Here’s how inventory management software can help:

- Real-time monitoring of inventory levels so you can make replenishment orders and decide what to do with unsold inventory.

- Integrations for ecommerce platforms, ERPs, and other apps in your tech stack.

- Multi-channel inventory tracking, which is helpful when you sell through multiple sales channels like brick-and-mortar, online store, and others.

- Ecommerce automation features minimize manual work and risk of human error.

- Eliminates the need for manual inventory counts and gives you inventory data based on your chosen inventory recording method, such as FIFO (first in, first out) and LIFO (last in, first out).

- Makes related tasks such as inventory auditing, order management, and warehouse management easier.

5 Benefits of Ecommerce Inventory Management

Once you know how to manage ecommerce inventory, you’re in a better position to improve your business’s inventory efficiency, cash flow management, and profitability.

The following is a list of benefits you can expect to get out of planned and consistent ecommerce inventory management.

1. Optimized Profitability

Inventory has various expenses associated with it, including:

- Carrying costs.

- Ordering costs.

- Cost of obsolescence.

- Opportunity costs.

The problem is that online retailers can’t monitor these costs with spreadsheets. On the other hand, small businesses don’t feel fully confident about investing in inventory management solutions because of the associated cost.

However, when you use inventory software, you get the data you need about inventory-related costs. Once you have this information, you can formulate an inventory management strategy (with methods like EOQ and ABC) to minimize your costs and optimize profitability.

2. Cash Flow Management

Businesses can fail because of poor cash flow management.

Even though it might seem that you possibly can’t free up any significant amount of cash by managing inventory well, you’ll be surprised just how effective this additional working capital can be when you’re in a cash crunch.

3. Better Internal Controls

If you have warehouses in multiple locations, there’s always a risk of theft. When you don’t monitor exactly where your inventory is going, it gives an employee a chance to misappropriate it.

An inventory system empowers you to set up internal controls that can provide better visibility over your inventory.

Bigger brands like Amazon and eBay have a team of internal auditors, but small businesses usually can’t afford to hire such teams. That’s exactly why a robust inventory management process — supported by inventory management software — is crucial for better control over inventory.

4. Minimized Order Costs

Every time you place an order, you incur costs like freight and use up human resources in the receiving department and warehouse. The fewer orders you place, the better it is for your bottom line.

Implementing the EOQ technique helps minimize ordering costs. You’ll always be more prepared with restocking and able to place orders consistently with your suppliers — which makes them happy, too.

5. Complete Information for Forecasting

The more historical data you have, the more accurate your forecast will be. Note that this is only probabilistically true. Your forecast may still be off in cases where the world is hit by a pandemic, for example.

It’s unlikely that you’ll be able to forecast exactly how much you’ll sell during a given time frame.

However, having a framework helps get a sense of how much you need to order and how frequently. You might also be able to identify and plan for potential supply chain management issues.

Final Thoughts: Ecommerce Inventory Management

As an ecommerce store, inventory is at the center of your business. Ideally, you should use platforms and tools that enable better control over that inventory.

WooCommerce, the best ecommerce solution on WordPress, offers several built-in options for ecommerce inventory management under Settings > Products > Inventory. You can assign SKUs, set up triggers for fast-moving items, and do much more with the platform’s inventory management options.

Want to get started with WooCommerce? Check out Nexcess’ Fully Managed WooCommerce hosting packages today.